Our Work

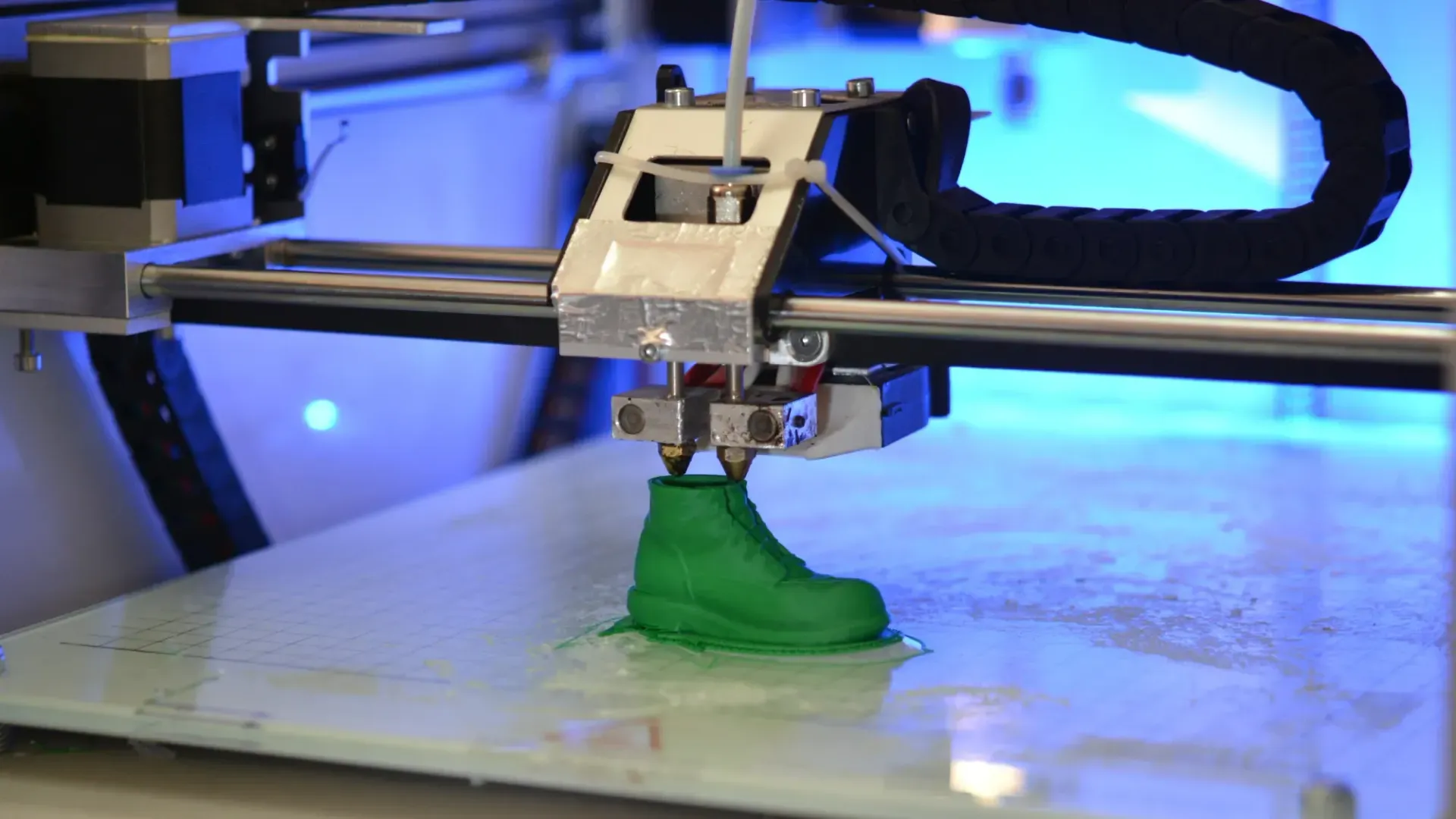

Importation of 3D Models

By Utilising customer 3D files, we are able to efficiently and effectively import design data to ensure optimal quality requirements are consistently met during the Manufacturing process

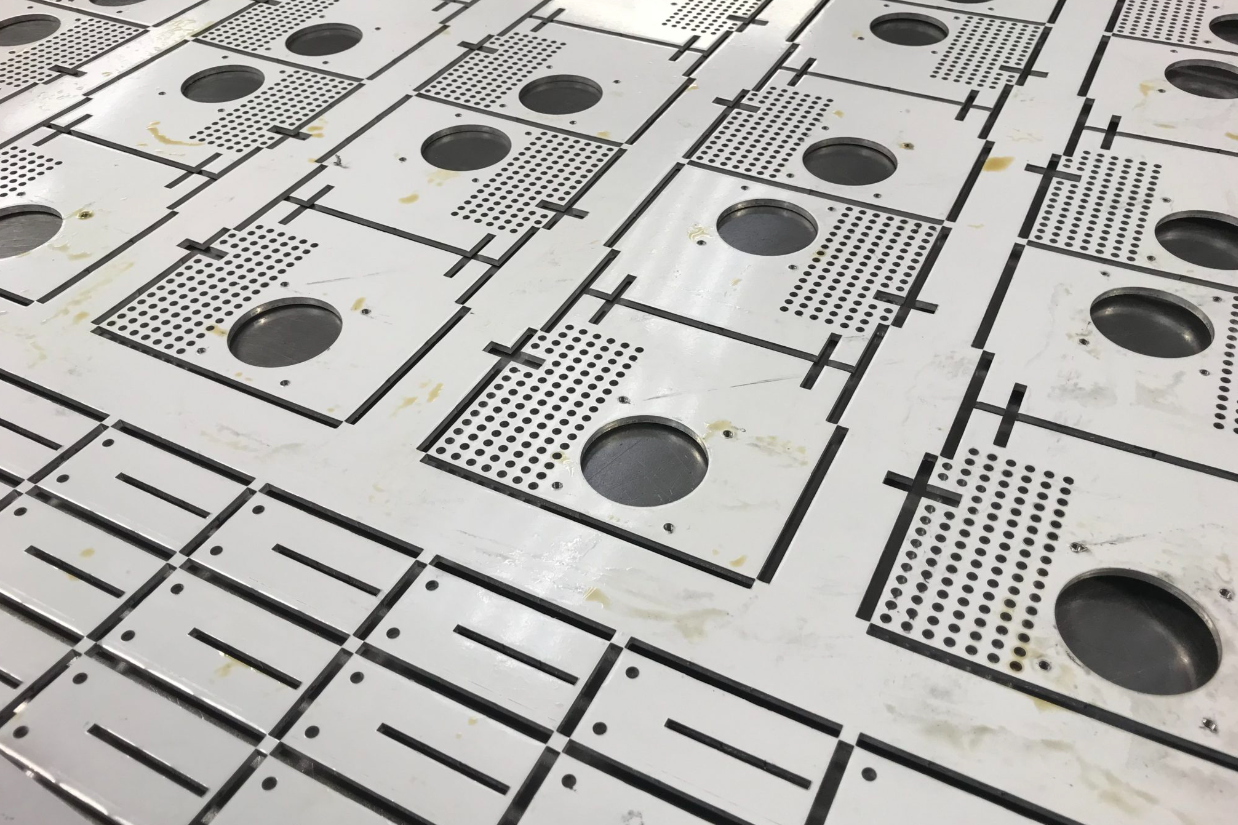

Wide variety of Manufacturing capabilities

We have a full range of the best and latest Sheet Metal manufacturing equipment to ensure that we can produce the highest quality parts in the shortest possible times. This ranges from CNC Punching and folding equipment, to a full suite of welding and screen printing facilities

Full-Service Processing

We work closely with our manufacturing network to ensure that we are able to provide the full compliment of finishing requirements, whether it be a specific plating or paint requirement, or just a raw de-burred finished component - either way TL Engineering have it covered.

We have a wide variety of manufacturing capabilities to meet your needs.

Please browse below for examples of our offering.

New Paragraph

New Paragraph

New Paragraph

New Paragraph

New Paragraph

New Paragraph